The Race to Scale Supershoes

Today’s newsletter has been waiting to be written for quite some time.

As most of my long-time readers know, I’m a recreational and, more recently, a marathon runner. And here comes a little flex: I just got accepted into the upcoming Boston Marathon, often considered the pinnacle of amateur marathon running. This year, it was one of the hardest to get into, with a time cutoff requiring people aged 18–34 to run under 2:53:09 to qualify and people my age (those who know, know) to run under 3:18:09.

But why is it becoming harder to qualify? Aside from the increasing number of people running due to work-from-home flexibility and pandemic fitness habits, there’s another factor at play—super shoes!

For those who are less familiar, super shoes are a revolutionary advancement in running footwear, which combines improved foams with carbon-fiber plates, and are designed to increase energy return to propel runners forward faster.

Let’s start with the simple facts: These shoes are expensive AND hard to find.

I’ve personally run marathons (and half marathons) in the Asics Metaspeed Sky+, the Nike Vaporfly 3, and the Adidas Adizero Pro Evo 1. Marathon world record holder Tigist Assefa famously wore the latter one. They retail for $500, and only 521 pairs were released to the general public. How did I get a pair? The firm ran a lottery, and I “won” the right to buy one.

(In case you’re wondering if I’m worthy of a pair, the answer is, of course, no. Was it fun running in them? Absolutely!).

But high prices and limited availability are not unique to Adidas. The Nike Alphafly 3, which costs $285, stocked out within 2 minutes of being first offered to consumers.

But what makes these shoes so expensive, and how can manufacturers scale without losing their technological edge?

Today’s article doesn’t focus on whether these shoes make runners faster (they do, the same way the use of electrolytes and gels “enhance performance” during a race), but rather on the challenges and implications of scaling these advanced shoes, given that most of them stock out within minutes upon becoming available.

Core Components: The Carbon Plate and Foam

Let’s dig deeper into the super shoe construction by focusing on their core components and how they’re manufactured.

Carbon Plate: Precision and Performance

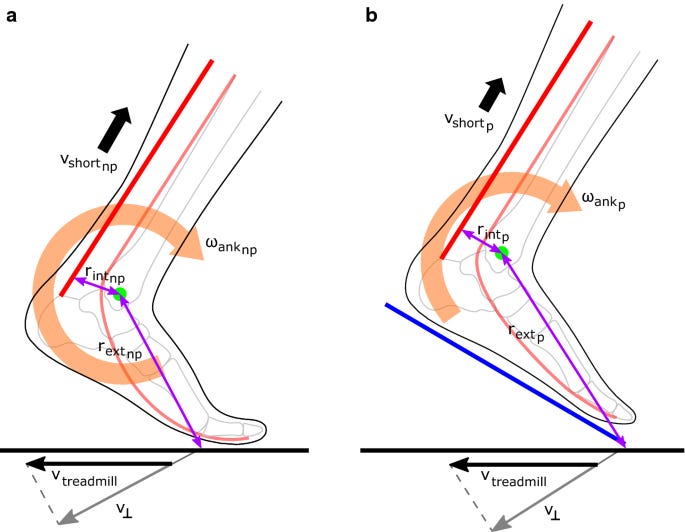

At the heart of the super shoe revolution is the carbon plate, and while it may seem like a simple insert, its manufacturing and impact are far more complex. The carbon plates used in running shoes, like Nike’s Vaporfly and Adidas’s EnergyRods, are designed to harden the shoe and improve running efficiency. These plates reduce the bending of the metatarsophalangeal joint (the joint where your toes meet your foot), saving energy that would otherwise be spent stabilizing the foot during push-off (the diagram below is for those who care).

Carbon plates are made from carbon fiber sheets, which are lightweight, rigid, and have high tensile strength.

The manufacturing process begins with carbon-fiber-reinforced polymer laid out in sheets and cured using heat and pressure. For the curved plates in Nike’s Vaporfly or Adidas’s EnergyRods, the sheets are placed in molds that give the plate its specific shape. The curvature of the plate is critical for optimizing energy return, with studies showing that more curved plates (like those in Nike’s shoes) also reduce strain on the calf muscles.

Adidas introduced an innovation with their EnergyRods —thin, segmented rods mimicking the structure of the foot’s metatarsal bones— which are embedded separately in the midsole rather than as a single plate. This provides more flexibility for different footstrike patterns. The rods are made from the same carbon-fiber material, but the precision required to insert them means they must be assembled manually in small production batches. This highly specific construction is one of the reasons the Adidas Evo 1 costs $500.

Foam Midsole: The Lightweight Powerhouse

Next is the foam midsole, arguably the most crucial part of modern super shoes. The foam must be lightweight, provide excellent cushioning, and, most importantly, return energy to the runner. The foam technology used in today’s super shoes is a huge leap from traditional ethylene-vinyl acetate (EVA), which dominated the running shoe market for decades.

Nike’s ZoomX foam, for example, is made from PEBA (Polyether Block Amide). This high-performance thermoplastic elastomer offers about 87% energy return, significantly higher than EVA foams commonly used in non-super shoes (you know what I mean). PEBA is known for its low density, high resilience, and resistance to extreme temperatures, making it ideal for high-performance sports.

PEBA foams are created using a supercritical fluid foaming process where supercritical nitrogen or carbon dioxide is injected into the molten polymer under high pressure, creating small gas bubbles within the foam as the pressure is reduced. This method allows manufacturers to carefully control the size and distribution of the bubbles, both of which directly impact the foam’s weight, resilience, and energy return.

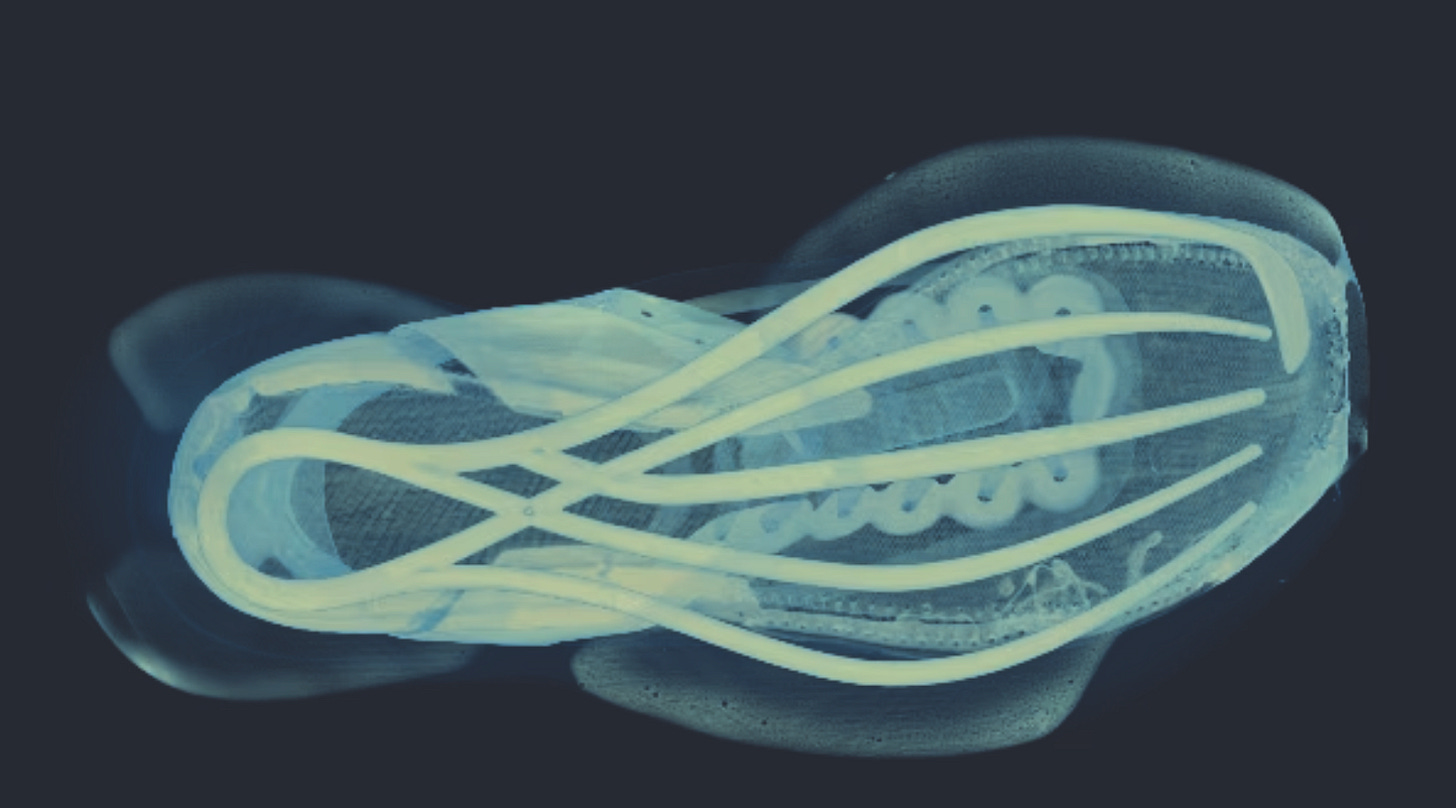

What sets the Adidas Adizero Adios Pro Evo 1 apart is its unique combination of high-performance foam and how its components are molded and assembled. Unlike traditional foaming methods, Adidas uses a proprietary technique to mold the Lightstrike Pro foam with ultra-precise tolerances. The midsoles are molded around the carbon EnergyRods, which are embedded during the foaming process. This allows the shoe to maintain its structural integrity without adding extra layers or adhesives, reducing weight by eliminating excess materials (as you can see in the x-ray photo below):

Moreover, the Evo 1 incorporates liquid rubber into the outer coating of the foam, a technique Adidas developed in-house to shave off an additional 20 grams of weight. This rubber layer protects the foam from wear and tear while maintaining the shoe’s lightness and grip on the road.

So, the more unique the shoe, the more expensive and less scalable it is.

Super Shoe Cost Breakdown

These steep prices—ranging from $275 to $500—can be explained by breaking down the costs involved in the manufacturing process:

Research and Development (R&D): R&D costs for super shoes are massive. For shoes like Nike’s Vaporfly and Adidas’s Evo 1, these costs include biomechanics research, material testing, and prototyping. It’s estimated that R&D expenses alone can make up 20–30% of the total cost of a shoe.

Materials: The materials used are far more expensive than those of traditional running shoes. High-performance PEBA foam and carbon-fiber plates are costly. The Bill of Materials (BOM) for these shoes includes synthetic uppers, foams, carbon plates or rods, and other components, which together can add up to approximately $30–50 per shoe.

Labor and Assembly: Much of the assembly of shoes like the Evo 1, is still done by hand. Precision placement of carbon rods and the foam molding process requires skilled labor, particularly when integrating advanced materials. Labor costs can account for another 10–15% of the shoe’s cost, depending on where it’s manufactured.

Most running shoes, even high-end ones, are still assembled by hand, which drives up costs due to labor and the precision required for cutting and assembling components. If you’re wondering whether the process is still manual in 2024, you must watch this video.

Adidas, however, is looking to change that by investing in robotic factories that can create shoes faster and with greater precision than humans. Their “Speed Factories” are designed to make fully customized shoes on demand, with robots completing most of the work, cutting production time from weeks to hours. Adidas’s robot-driven plants can complete a pair of shoes in just five hours. This cuts labor costs and allows for more customization and waste reduction, as robots can work with more precision and avoid excess material usage.

Right now, the technology is only producing prototypes and limited batches, but the potential is evident. Robotic factories reduce the reliance on low-cost labor in emerging markets, which could radically shift where shoes are produced and reduce costs over time.

Manufacturing Overheads: Even with robotic factories, there are significant overheads involved in setting up and maintaining these production lines. This includes machine maintenance, quality control, and the cost of raw materials. Overheads might add another 5–10% to the total cost.

Marketing and Distribution: Super shoes are marketed heavily, especially through professional endorsements from elite runners like Eliud Kipchoge and Tigist Assefa. Marketing costs, including endorsements, retail markups, and distribution, can take up as much as 40–50% of the total cost.

Retailer Margins: The final markup happens at the retailer level. In the case of Evo 1, Adidas is the only outlet, so the margin goes directly to the firm.

Beyond cost and lack of scalability, another issue with super shoes is their longevity and, thus, sustainability. For example, running more than one marathon on the Evo 1 is not recommended.

As Patrick Nava, Adidas’s Global Vice President of Product Management for Running, said, “We didn’t build the shoe to last 1000 miles” because professionals prioritize peak performance, not longevity.

Component Commonality: The Key to Affordability and Innovation in Footwear

But there’s a positive side to all this investment.

Recently, Adidas launched the Adidas Evo SL, and their Global VP of Product Management discussed the creation of the shoe:

“The thing about Adizero is that you have a stiffening element basically all the way through until you reach the SL2. What if we took the geometries like the EVO & Pro 4 but it didn’t have a stiffening element from heel to toe in it? What kind of running shoes would it make? It was a little bit of an experiment and that’s how the Evo SL was born. It was the idea of bringing that fast feeling but to a little bit of a democratic approach. The Evo 1 and the feeling that you’ve got is not exactly for everyone, but what if we could tune it into more of a democratic direction.”

The idea? Component commonality.

Component commonality refers to using the same parts or technologies across a range of products, allowing manufacturers to reduce costs, streamline production, and make advanced technology more accessible. It is a widely used strategy in industries like automotive, electronics, and footwear. This practice enables companies to develop cutting-edge products and then distribute the technology across different price points without investing in entirely new R&D and production processes for each new model.

In simple terms, component commonality involves creating a shared pool of resources—whether materials, technologies, or designs—that can be applied across multiple products. In the automotive industry, many manufacturers use the same engine platforms, suspension systems, or electronic systems across different models. For example, Volkswagen’s MQB platform is shared across models like the Golf, Tiguan, and Audi A3. This allows the company to produce a wide range of vehicles at different price points using the same fundamental architecture.

This strategy is not just limited to physical components but can extend to software, processes, and design frameworks, maximizing efficiency and lowering the cost per unit. In industries with high costs of innovation and research, such as the semiconductor industry, using the same core technologies across multiple devices allows companies to recoup their initial R&D investment across a broader array of products.

In the footwear industry, component commonality has become a critical strategy, particularly in developing high-performance running shoes. Brands like Nike, Adidas, and Asics leverage this approach to introduce innovations at the elite level and then cascade those technologies to more affordable shoes.

For instance, the Asics FlyteFoam Blast Turbo foam—originally developed for high-end models like the MetaSpeed Sky+—has since been used in shoes like the Superblast. Similarly, Nike’s ZoomX foam, which powers their Vaporfly and Alphafly super shoes, now appears in training shoes like the Pegasus Turbo and Invincible Run.

There are several key advantages to using component commonality in the production of running shoes:

Cost Savings: By using the same advanced materials across multiple models, brands can amortize R&D costs over a wider range of shoes, thus lowering the price for consumers. For example, once the research behind an advanced midsole foam is completed, using that same foam in lower-tiered models significantly reduces the technology’s cost per-unit.

Scalability: With a common components platform, manufacturers can scale production more efficiently. This is particularly important for companies that produce large volumes of shoes in various markets, as it allows for consistency in manufacturing without having to retool for each new model.

Faster Time to Market: Developing entirely new components for every shoe model can delay production. Component commonality accelerates the product development cycle, enabling brands to bring new models to market faster by incorporating pre-existing, well-tested materials and technologies.

Quality and Reliability: When components have already been proven in elite-level shoes, consumers can trust that the same technologies will perform well in the lower-tier models. Using tried-and-true materials reduces the risk of failures and defects, ensuring that even affordable shoes meet high-performance standards.

As brands refine their use of standard components, consumers can expect even greater access to high-performance footwear at various price points, further democratizing the benefits of advanced running shoe technology.

The Innovation of On’s “Sprayed-On” Shoes: Revolutionizing Shoe Manufacturing

For consumer electronics, a critical decision is whether to use a modular or integral design. The iPhone follows an integral design, while most desktop computers remain modular (each component is mapped into a function). Shoes are still integral, but the notion of component commonality can be seen as a step toward modularity, making shoes more affordable.

However, the opposite approach can achieve similar affordability and may be more sustainable. This is what On Running is attempting with the introduction of LightSpray technology, debuting in their new Cloudboom Strike LS running shoe.

LightSpray technology represents a precision-engineered manufacturing process developed by On Labs in Zurich.

Unlike traditional multi-step shoe construction, LightSpray uses a robotic arm to apply liquid materials directly onto the shoe mold, creating an ultra-light and seamless, one-piece upper. This eliminates the need for stitching or adhesives, which are common in traditional shoe assembly. The automated process ensures a high level of precision, producing shoes that offer an unparalleled fit and support, perfect for race day.

The Cloudboom Strike LS’s one-piece upper is ultra-thin, providing a distraction-free experience for runners. The seamless design eliminates the need for laces, allowing for a more aerodynamic and minimalist profile, which is perfect for elite runners like Hellen Obiri, who won the 2023 Boston Marathon in an early shoe version.

Additionally, the spray-on process’s flexibility allows for greater customization. For example, On could adjust the thickness or composition of the material depending on the specific needs of individual athletes or different race conditions.

You’re probably wondering whether this is even scalable.

One of the primary advantages of LightSpray technology is its potential for scalability and sustainability. Traditional footwear manufacturing is labor-intensive, requires multiple materials, and generates significant waste. In contrast, the fully automated LightSpray process significantly reduces waste by applying only the necessary materials directly to the shoe mold. According to On, this technology cuts carbon emissions by 75% compared to traditional race shoes.

Additionally, the production process is faster, requires fewer steps, and enables local manufacturing, which reduces transportation costs and time-to-market. The shoes are also made from a single recyclable material, promoting circular manufacturing and allowing for easier recycling at the end of the product’s life (recycling claims sound better on paper, so we’ll have to follow up on that).

Conclusion: The Future of Scalable Super Shoes and Super Trainers

The race to scale super shoes will depend on innovations in shoe design and performance, as well as in the manufacturing processes themselves. With the rise of robotic factories and advances in material science, the costs associated with making these shoes may gradually decrease, making them accessible to a broader audience. However, the high R&D costs, the precision in crafting, and the limited production runs will continue to keep these shoes in the premium price range for the foreseeable future.

The next major hurdle for companies like Adidas and Nike will be finding the sweet spot between performance and scalability, ensuring the benefits of super shoes reach not just elite athletes but also everyday runners. The key to this lies in leveraging component commonality. And as the race to scale continues, we’re likely to see more innovation, not just in the shoes, but also in the processes used to create them.

So, as I prepare to lace up for Boston, if you’re a loyal newsletter reader and happen to be around on Patriots’ Day (the day of the Boston Marathon), come cheer me on! It’s 96% training, 4% super shoes, and 100% me needing all the support I can get—because, let’s be honest, a shoe can only do so much, even if it is super!

Great article! The only thing missing is a newsvendor model...